REATISS Unlock patent value

Services

Product Analysis

Product Analysis

This analysis can be helpful for a customer in a different ways:

- Compare competitor product with similar products within a customer products

- Find the outstanding features of competitor product

- Improve the competitive position on the market

- Benchmark against future technology plans

REATISS provides several fundamental types (levels) of analytical reports to gain a wider understanding of the package and silicon processing techniques utilized by the competitive devices.

It serves for decision making regarding further analysis steps.

Report contents:- Package photos, marking

- Package X-Ray

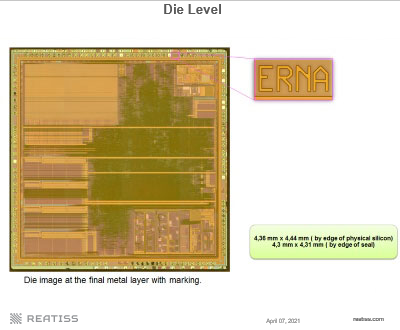

- Photo of die at top metal level

- Photo of die markings

- Die and package dimensions

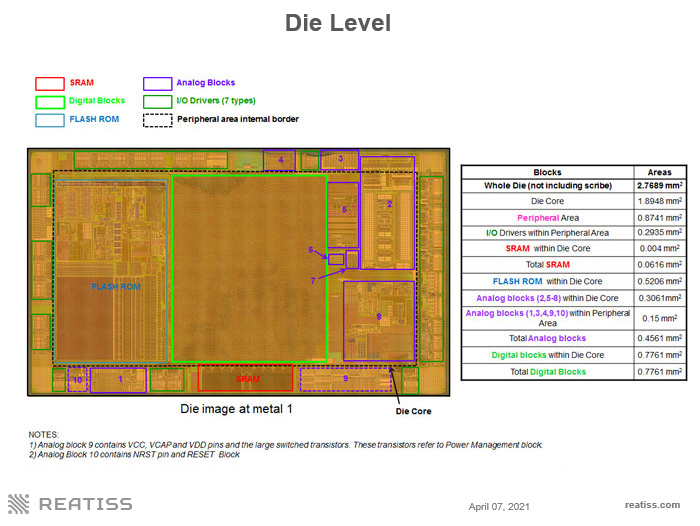

For this purposes the die is de-processed down to Metal1 or Diffusion level. The deliverables can be used for comparison with the customer own product and drawing conclusions regarding the die area utilization.

Report contents:- Package photos

- Package X-Ray

- Photo of die at top metal level

- Package X-Ray and die combined image

- Die and package dimensions

- Photo of die markings

- Photo of die at metal 1 / diffusion level

- Boxing of the different blocks

- Table account for the total die size per block (Flash, RAM, Analog blocks, Digital, Core area, total die)

-

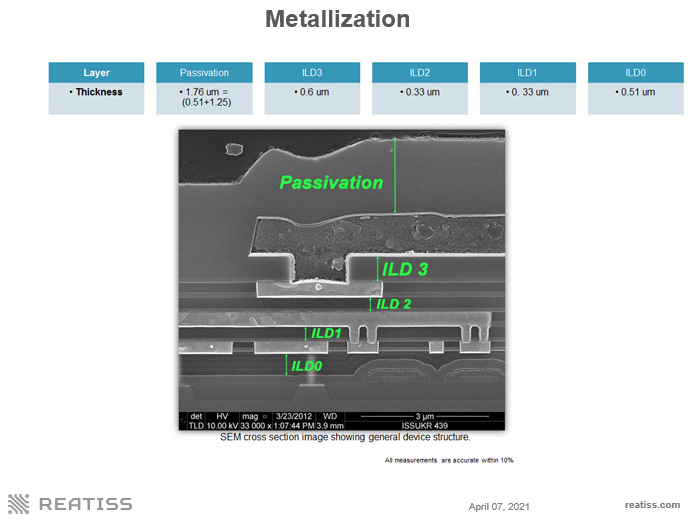

Technology analysis

- # of metals, metallization materials

- Vertical dimension measurements

- Cross section images showing general device structure

- Gate length measurements

-

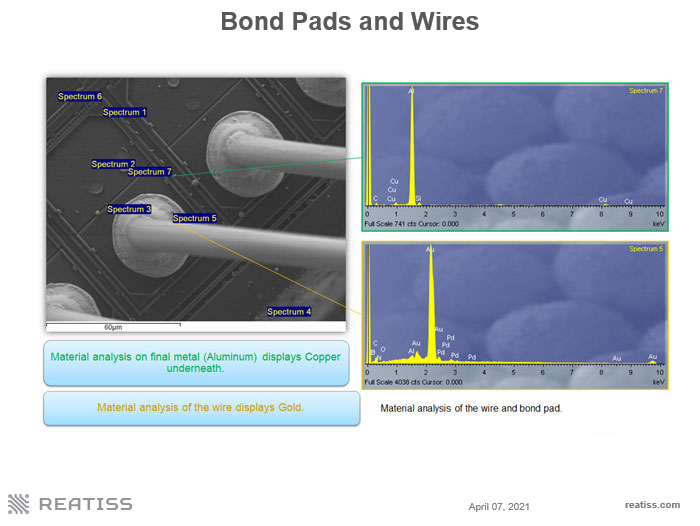

Bond pads

- Image of die fragment and bond pads

- Bond pad blowup image

- # of pads, pads bonded out

- Pad measurements

-

Standard cell analysis

- High-resolution top-down image in the sea of gates at M1 or poly

- Standard cell size measurements

- Cross section of MOS devices, gate length measurements

-

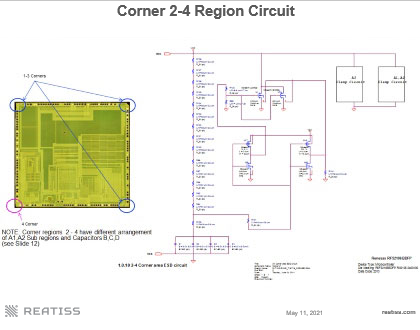

Functional analysis

- Major functional block identification

- Size measurements for major blocks

- High resolution images of major blocks

-

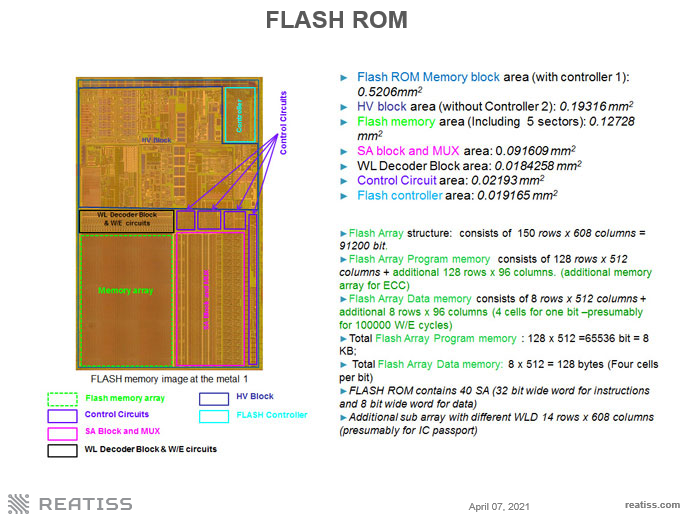

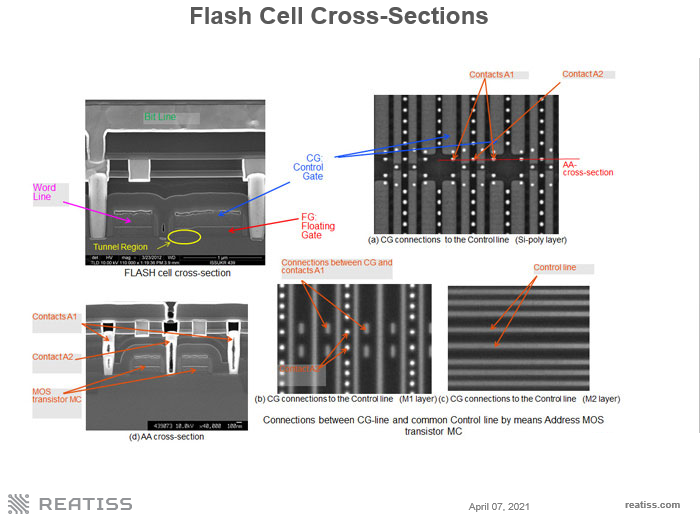

Memory analysis (Flash, SRAM)

- High-level structure

- High-resolution top-down bit cell image at M1 or poly

- Bit cell size measurements

- Efficiency calculation

- Flash cross section, feature size measurements

- Digital/analog schematics organized in a hierarchical manner (I/O Buffers, SRAM, FLASH, PLL, ADC, focused extraction of sea of gates etc.)

- Signal tracing

- Transistor-level details

- Access to a high resolution layout image data base (focused areas/full die)

The results received through a package cross sections, material analysis, and physical dimension measurements. A customer may define particular areas of interest in order to perform benchmarking with own product in a most efficient way.

Standard report contents:- Package photos

- Package X-Ray with construction dimensions.

- Die top metal: die photo, dimensions, marking;

- Bond pad photos with dimensions; wire measurements.

- Inspect die edge for chipping/peeling.

- Package cross-sections (through the leadframe, terminals, die): material analysis, construction detailed photos, measurements.

As a part of service, REATISS provides constant support and response to engineering requests for clarification of the data and additional information on a competitive die/package.